CONTRACT BREWING AND BEVERAGE

SERVICES TO HELP GROW YOUR BRANDS

Founded in 2016, we are a South India-based brewing contract packaging manufacturer.

AMERICAN BREW CRAFTS LIMITED was founded by an industry visionary and established American NRI entrepreneurs. A.B.C. is managed by an expert team with more than 2-3 decades each of experience working with national and multinational brands to help bring the finest quality and award-winning beverage brands to markets across the globe.

An Experienced Co-Pack Partner

Our facilities in Near Hyderabad, Near Kakinada are capable of producing in excess of five million cases of beer/beverage annually and we have both the technical expertise and requisite licensure to produce beer and seltzer.

.PNG)

INFRASTRUCTURE AND EQUIPMENT TO MEET YOUR NEEDS

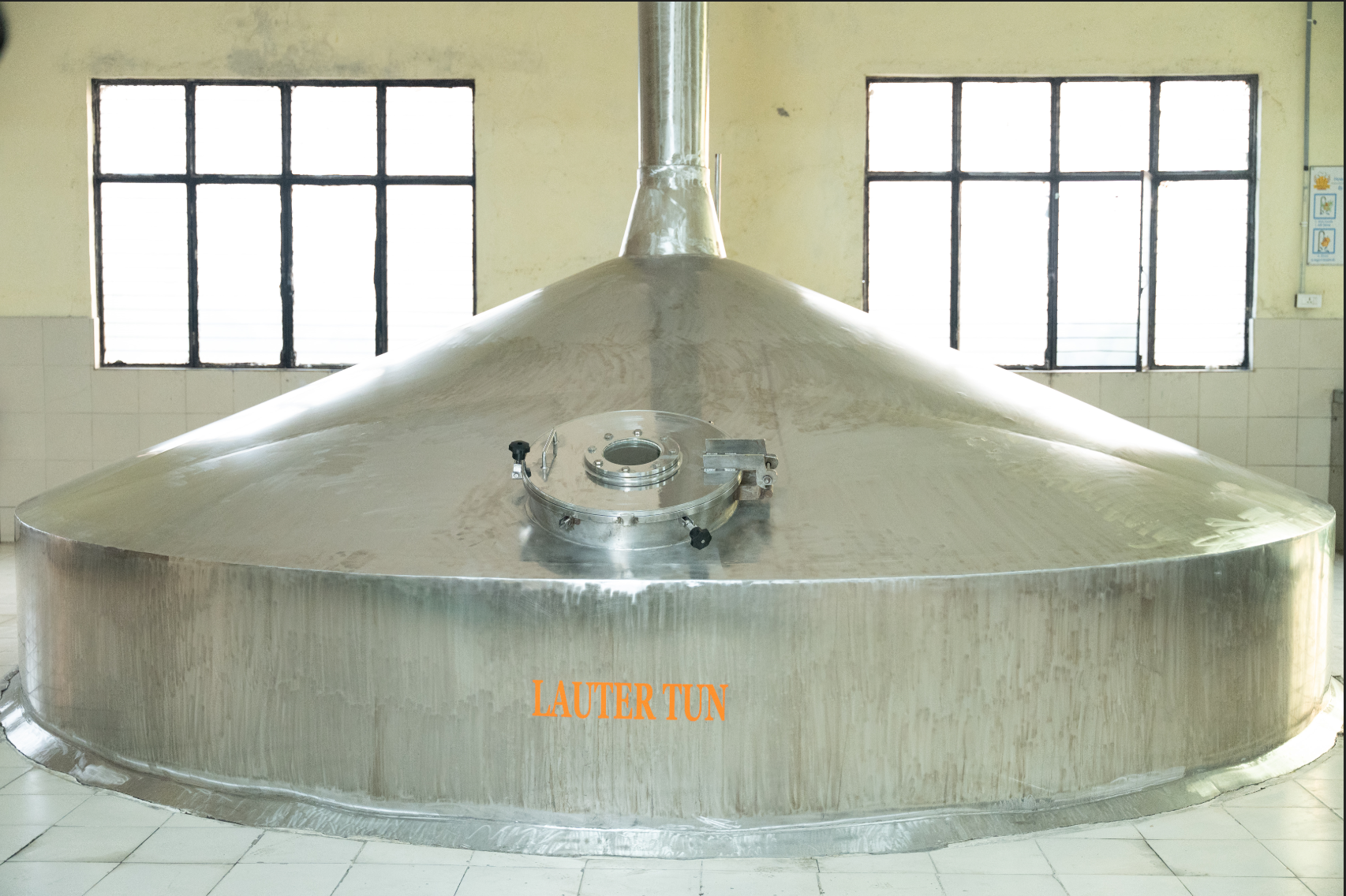

We operate a 200 HL brewhouse with Alpha Laval Brewhouse and Centrifuge. The packaging hall is equipped with high-speed KHS canning and bottling lines capable of filling most common vessel sizes and packaging into myriad configurations. Contract customers are able to leverage ABC's established network of freight and warehouse operators as well as component sourcing and supply chain.

PEOPLE POWER

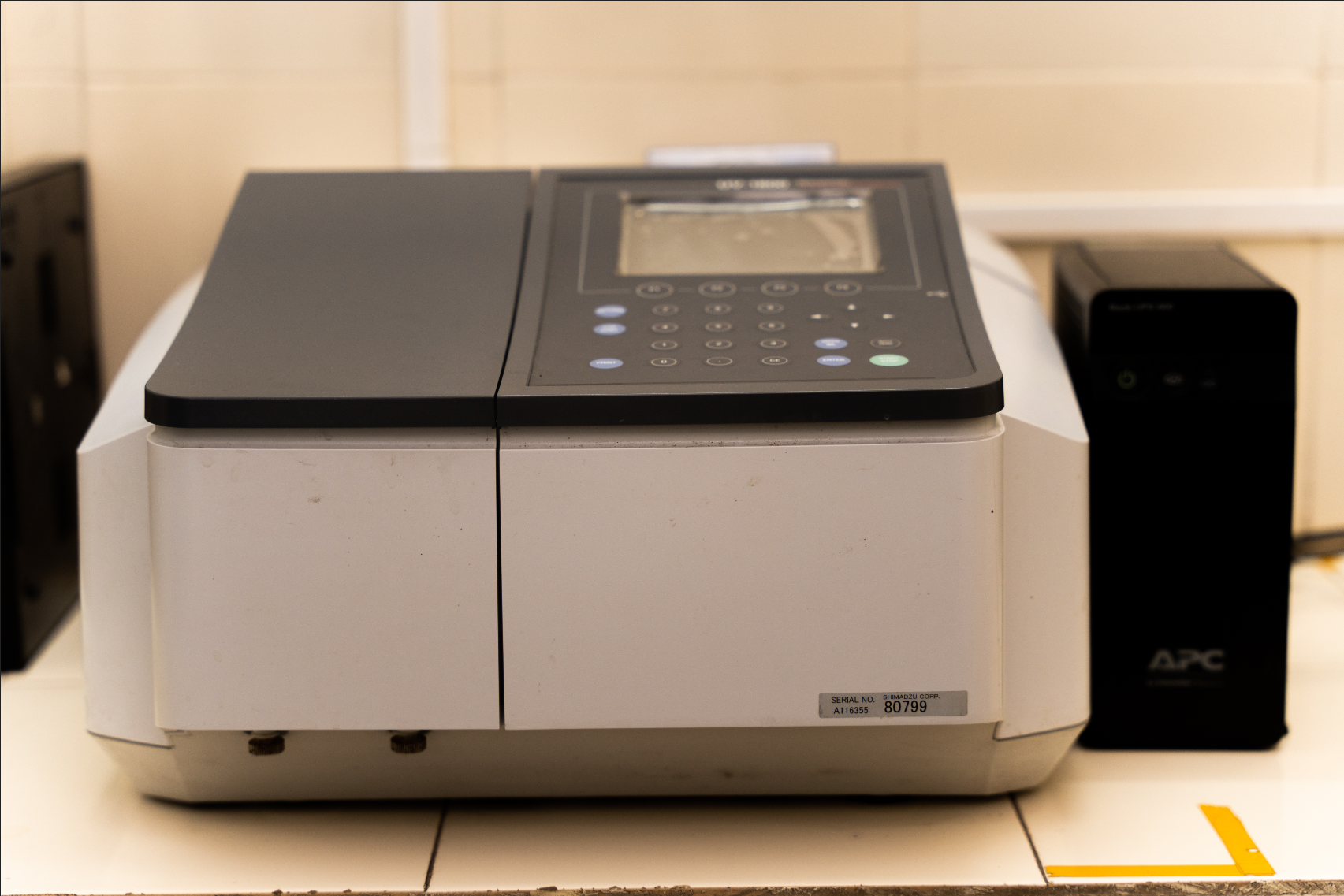

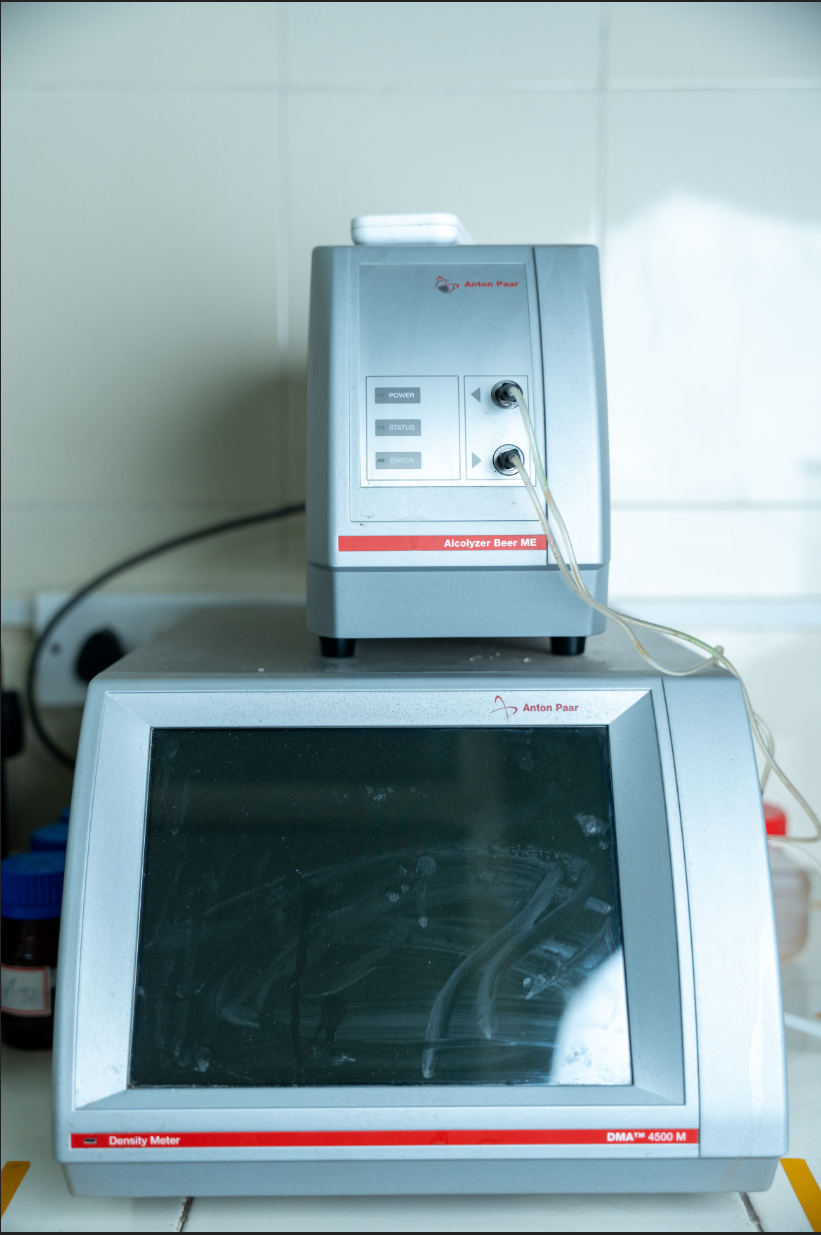

Knowledge and know how run deep at ABC. We have a robust, state of the art lab and QA department to ensure that every drop of liquid leaving our facility is of the highest quality. Additionally, The Institute of Brewing & Distilling qualified Master Brewer A.Tamilarasan has spearheaded multiple new product developments and launches. It’s no wonder ABC brands have won many awards & gold medals through the years!

.PNG)

.PNG)